Introduction

About Flexjoint

Flexjoint is a globally recognized leading supplier of waterproof expansion joints for roofing and waterproofing applications.

Flexjoint waterproof expansion joints are specifically designed and engineered for use in a wide variety of applications, ranging from single ply membrane tie-ins to large-scale displacement seismic joints.

Our solutions are compatible with, hot rubberized asphalt, modified bitumen, asphalt based membranes as well as cold adhesives.

Please note that Flexjoint EP has replaced the previous Yellow product. Flexjoint EP has better shear performance and works as well with epoxy, torch-on or any liquid waterproofing material.

Key Features of Flexjoint EP:

- New or Retrofit roofing and waterproofing applications

- Monolithic Joints with vulcanised seams

- High resistance to most chemicals

- Suitable for fixing to concrete or bitumen

- Flat profile - no raised curbs

- Can be torched or epoxied

Warranty

Warranties of up to 20 years on this system may be available, depending on the nature of the project, and by negotiation only.

Please contact Flexjoint for details applicable to your project.

Australia & New Zealand Building Code Compliance

Flexjoint EP complies with relevant sections of the AUS & NZ Building Code.

Please contact us for a Product Technical Statement.

Applications

Roofing & Waterproofing : New or Retrofit

Expansion joints are present in all types of buildings. Expansion joints found in roofing have been a leading cause of leaks.

Flexjoint has solved this problem. Our waterproofing expansion joints provide a continuous waterproof expansion joint system, without the use of adhesives, glues and clamping plates. All Flexjoint expansion joints can be used in new or retrofit roofing and waterproofing construction.

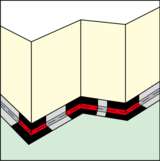

Flat Profile - No Raised Curbs

The conventional expansion joint is not waterproofed. Its raised profile is a result of necessity, since the assembly does not provide any waterproofing protection

All Flexjoint expansion joints are waterproof, which not only waterproofs the joint, but also seals the building's interior from the elements.

Water Drainage - Less Ponding

Ponding water is one of the leading causes of membrane deterioration in roofing and waterproofing. The raised curb of the conventional expansion joint restricts the free flow of water to drainage points.

Flexjoint's flat joint profile allows for water drainage and incorporation of the joint detail into the roof construction, without obtrusive raised curbs to restrict water flow.

This reduces the requirement for added drainage design.

A Monolithic Joint - Vulcanized Seams

Conventional expansion joints fail at the seams. The seam is the most vulnerable part and requires continuous maintenance throughout its service life.

All Flexjoint expansion joints are manufactured from an elastomer which allows for the vulcanisation of joint pieces, resulting in a monolithic joint which is seamless and maintenance free. The result seam is as elastic as the base material.

Custom Details - Factory Fabricated to Site Conditions

The layout of expansion joints do not follow straight lines. Frequently they are laid out along column lines and zigzag from column to column. The layout of such expansion joints requires considerable detailing effort at changes in direction, as well as at their termination.

Flexjoint joints can be custom fabricated to conform to any site detail, no matter how complex. One of the features of a Flexjoint joint is it reduces a 3 dimensional detailing problem to 2 dimensional.

Labour Savings - Efficient Installation

The construction of conventional expansion joints is labour intensive. Typical expansion joint construction has a number of different components, including wooden nailers, and metal flashing, all very time consuming.

Flexjoint expansion joints are delivered to the contractor with all details included in one seamless roll. Installation is quick and problem free, requiring little on site seaming or detailing.

Performance Information

Material Characteristics

The elastic material for Flexjoint EP consists of an EPDM elastomer (ethylen-propylen-diene unvulcanized rubber with saturated polymethylene main chain) with the following properties:

- excellent properties for protecting against attack from ozone and uv

- long term high temperature resistance (up to + 90° Celsius)

- long term high flexibility at low temperatures (down to - 40° Celsius)

Limitations

Low resistance to homopolar emollients and solvents (e.g. mineral oils, benzene, fuels and aromatic compounds, such as toluene).

Prolonged contact with these agents should be avoided.

Contact during the installation phase with the torch will not impair the material properties.

Expansion Specifications

Physical Properties

| Characteristics | Units of measure | Specifications | Values | Tolerance |

|---|---|---|---|---|

| Hardness (H) | Sh. A3 | ASTM D 2240 | 45 | ±5 |

| Tensile strength (CR) | MPa | ASTM D 412 C | > 10 | min. |

| Elongation at break (AR) | % | ASTM D 412 C | > 500 | min. |

| Tear strength | N / mm (.) | ASTM D 624 B | > 10 | min. |

| Abrasion resistance | mm3 | DIN 53516 | ||

| Specific gravity | g / cm3 | DIN 53479 | 1,05 | ±0,03 |

Further Data

Further information, including Material Safety Data Sheets and comprehensive application details, are available at flexjoint.co.nz

Site Photographs

Sample Details

Please note the these are just a few of the available details - please see our Construction Details Page for more.